As per US statistics, a CNC machinist’s annual salary was around $42k in 2023. Like various industries, the salary of the machinists can be extremely high depending on the organization, their specialty, level of experience, and requirement of work.

Since the demand for CNC machinists is rising with the importance of automatic systems, those who are trained in this field can grab some amazing opportunities from the big organization around the world. Gone are the days when CNC machinists were particularly required for making parts for cars and military equipment.

Nowadays, almost every product is created with the help of these machines. We can expect that every manufacturing company will soon start hiring a team of CNC machinists because of the growing demand for several products related to dental and medical parts.

In this article, we’ll discuss what CNC programming is, why you should learn it, and how to get started.

Should you learn CNC machining?

This method has been used in manufacturing for many years and is becoming more popular as technology advances. If you’re interested in manufacturing, or engineering, or just want to learn a new skill, CNC programming is definitely worth considering.

Programming itself is a high-paying job now and it is one of those fields of work that will never be outdated. Rather, it can help other jobs to thrive in the tech-dominated workspace.

At Codeant, we teach kids and teenagers how to code and build robots on their own. So, what we are doing is being a channel to prepare your kids for a great future of high-end tech innovations.

But before your kids can go into CNC programming, we have some of the basics and fundamentals of programming for kids and beginners.

Also, we take kids on robotics and some theory-related context of AI technology.

If you have a mechanical and technical mindset with good calculative and decision-making skills, then you can learn CNC machining Singapore. You have to be focused and detail-oriented. Moreover, you will be required to take decisions quickly and follow the directions that are provided to produce the product.

One thing to keep in mind is that you will have to operate the machine and modify the code when the output is not precise and desired. You must be ready to learn the best way to troubleshoot problems in a quick manner because there is a need to meet deadlines. Thus, the important quality that you must have is to work under pressure.

You have to think critically and be ready to take on challenges. The products that will be created using the CNC machine might not be as simple as you think, depending on the organization and their requirement.

Time required in learning CNC machining skills

The time that you will need to learn CNC machining skills mostly depends on the ability to understand and the kind of specialization.

Generally, students need 10-12 months to complete their machine learning program. You have to find a popular college or university to graduate and learn the skills, including operation of CNC mills and lathes, reading blueprints, and understanding the way to modify the program.

What is CNC Programming?

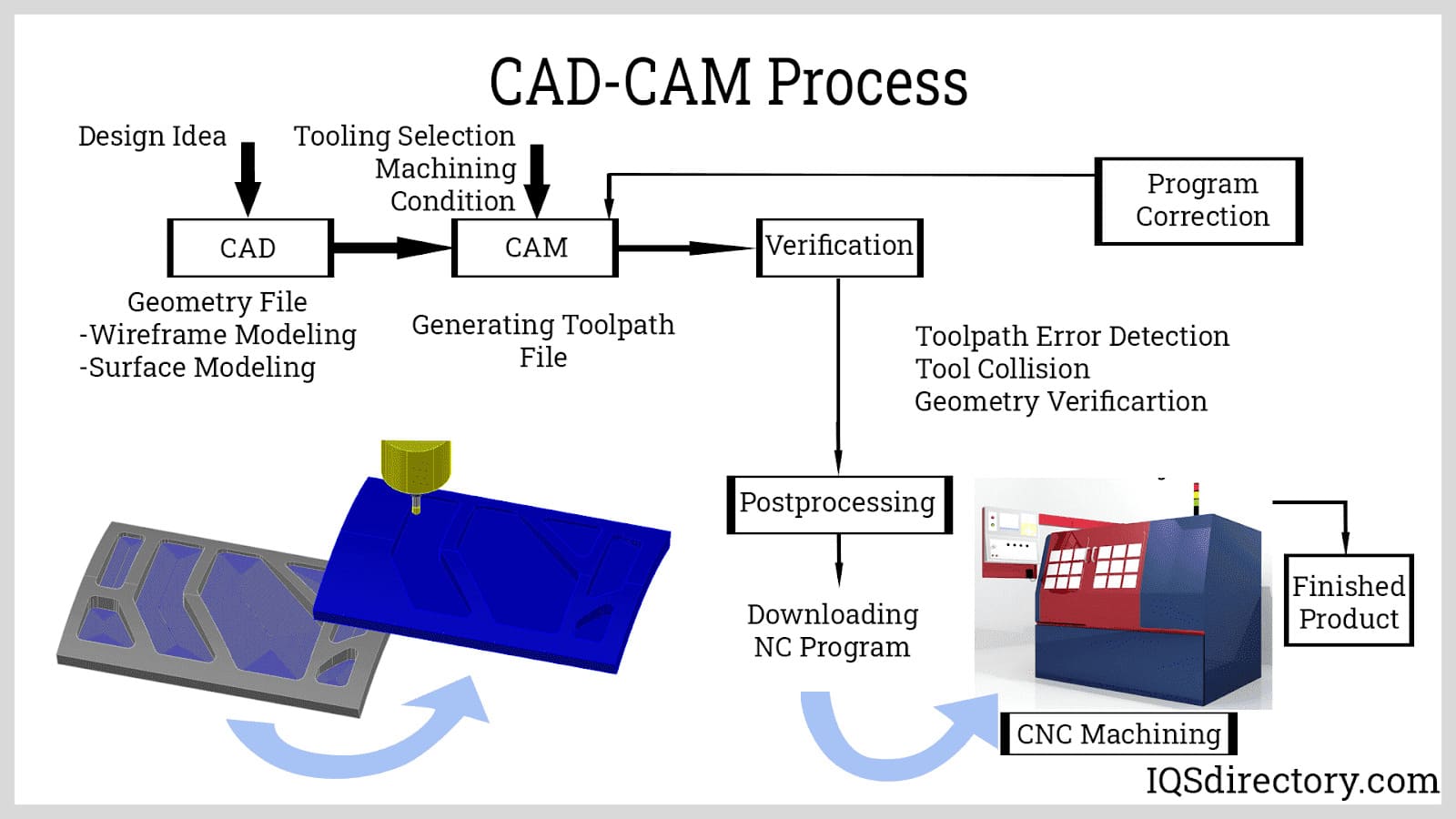

CNC programming is a method of controlling machines using a computer. The process involves writing a code that tells the machine what to do.

The code consists of a series of commands that the machine follows in order to complete a specific task.

CNC programming is used in a variety of industries, including manufacturing, aerospace, automotive, and more.

CNC machines are incredibly versatile and can produce complex parts and products with a high degree of accuracy. These machines can be programmed to perform a wide range of tasks, from drilling holes to cutting and shaping materials.

CNC programming is used to create a program that controls the machine’s movement, speed, and position.

Why Should You Learn CNC Programming in 2024?

There are many reasons why you should consider learning CNC programming in 2024.

Here are just a few:

1. High demand for CNC programmers

As the manufacturing industry continues to grow and evolve, the demand for skilled CNC programmers is on the rise.

Many companies are looking for individuals with experience in CNC programming to operate their machines and help them stay competitive.

Learning CNC programming can give you a valuable skill set that is in high demand.

2. High-paying jobs

CNC programmers are in high demand, and as a result, the salaries for these positions can be quite competitive.

According to the Bureau of Labor Statistics, the median annual wage for computer-controlled machine tool operators was $44,190 in May 2024. This can vary based on location, experience, and industry, but CNC programming can provide a good salary potential.

3. Versatile skillset

CNC programming is a versatile skill that can be applied in many industries. The manufacturing industry is the most obvious choice, but CNC programming can also be used in fields such as aerospace, automotive, and more. Learning CNC programming can open up a world of opportunities for you.

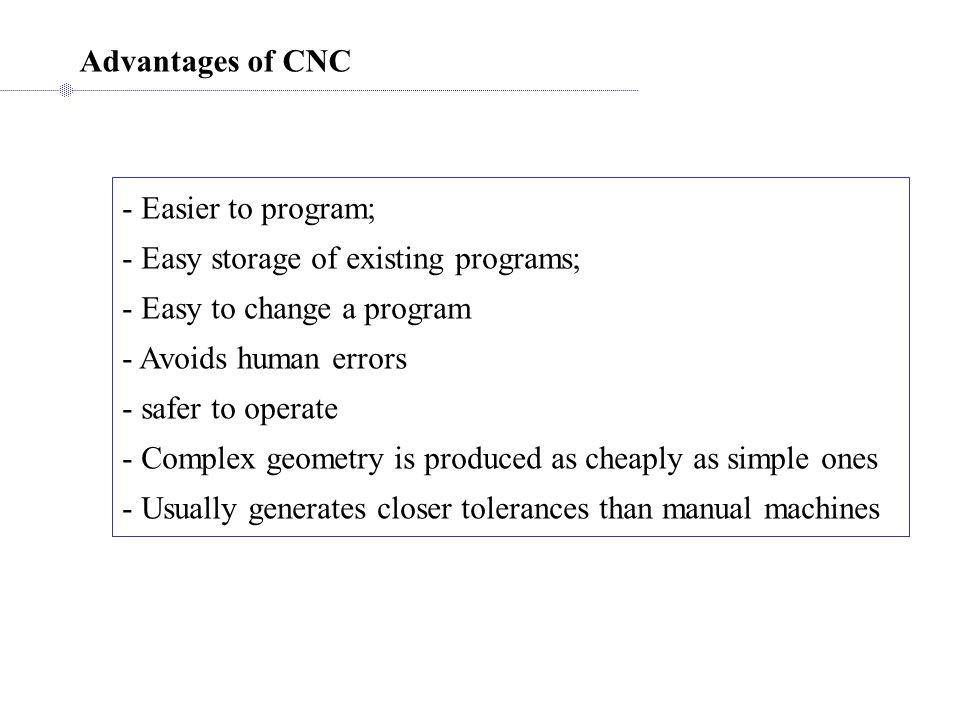

4. High precision and accuracy

CNC machines are incredibly precise and accurate, and CNC programming is used to control these machines. This means that CNC programming can help you create parts and products with a high degree of accuracy and consistency.

This is essential in many industries, such as aerospace and medical device manufacturing.

5. Automation

CNC programming is a form of automation that can help companies save time and money. By using CNC machines, companies can automate their manufacturing processes and reduce the need for manual labor.

This can result in higher productivity, lower costs, and faster turnaround times.

How To Get Started With CNC Programming?

If you’re interested in learning CNC programming, there are a few steps you can take to get started:

1. Research

Start by researching CNC programming to get a better understanding of what it entails. There are many resources available online, such as articles, videos, and tutorials that can help you learn the basics.

2. Training

Consider taking a course or training program to learn CNC programming. There are many options available, both online and in-person, that can provide you with the skills and knowledge you need to get started.

3. Practice

Practice not only helps you improve your skills but also builds your confidence, allowing you to take on new challenges and opportunities with ease.

Key Benefits of Learning CNC Programming

There are many benefits to learning CNC programming, particularly as we move into the new year.

As technology continues to advance and automation becomes more prevalent in manufacturing, the demand for skilled CNC programmers is only going to increase.

Reasons To Learn CNC Programming in 2024

1. More Job Opportunities

As mentioned earlier, there is a high demand for skilled CNC programmers, and this demand is only expected to grow in the coming years.

According to the Bureau of Labor Statistics, the employment of machinists and tool and die makers (which includes CNC programmers) is projected to grow 3 percent from 2020 to 2030, which is about as fast as the average for all occupations.

CNC programming skills are particularly valuable in industries such as aerospace, automotive, defense, and medical device manufacturing, which are all expected to grow in the coming years.

By learning CNC programming, you will have access to a wide range of job opportunities, both now and in the future.

2. High Earning Potential

Because of the high demand for skilled CNC programmers, these professionals are often well compensated.

According to Glassdoor, the national average salary for a CNC programmer in the United States is $62,000 per year.

However, depending on your location, experience, and skill level, you could potentially earn even more.

3. Improved Efficiency and Productivity

CNC programming allows manufacturers to automate many of the processes involved in producing parts and components, which can significantly improve efficiency and productivity.

By learning CNC programming, you will be able to create programs that optimize cutting paths, reduce scrap and waste, and ensure consistent quality. This can help manufacturers reduce costs and improve their bottom line.

4. Increased Job Security

As automation becomes more prevalent in manufacturing, the jobs that are most at risk are those that can be easily automated.

However, CNC programming is a highly skilled profession that requires a deep understanding of machining processes and the ability to create complex programs.

This makes CNC programmers less likely to be replaced by automation and provides a level of job security that is increasingly rare in today’s economy.

5. Career Growth Opportunities

CNC programming is a highly technical and specialized field, and as such, there are many opportunities for career growth and advancement.

As you gain experience and develop your skills, you may be able to take on more complex projects or move into management or supervisory roles.

Additionally, you may be able to specialize in a particular industry or type of machining, which can lead to even greater job opportunities and earning potential.

Conclusion

We hope now you understand who should learn CNC machine operating program and how much time they need to invest in learning the technicalities. You should find the best college so that they teach the most difficult concepts that can help in manufacturing huge products.

0 Comments