The technologies wouldn’t have developed so quickly and precisely without the use of precision engineering tools. There is a growing need for finer parts and only precision engineering can help in this scenario.

In this guide, we will learn the importance of precision engineering in the life of manufacturers. You should contact CNC machine programmers or precision engineers for getting help related to producing precise components.

Precision engineering is done to produce micro-parts and elements keeping in mind the tolerance ratio to meet the expectation of the industries like medical, filtration, electronics, automotive, and semiconductor. There can be different types of techniques and processes used in precision engineering.

Some popular tools used by precision engineers are laser cutting, photochemical etching, electroforming, laser micromachining, and micro stamping. The main advantages of precision manufacturing are less cost, more manufacturing ability, better performance of products, and improvement in science and technologies.

Most people don’t know about the importance of precision that is used by several manufacturers around the world to make parts in different shapes and sizes.

Process Of Precision Engineering

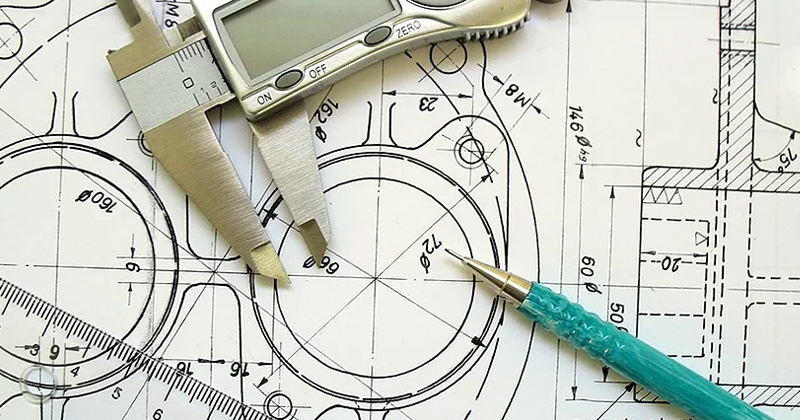

The highly accurate parts are provided to precision engineers for designing and developing purposes. Through the precision engineering process, the actual design gets converted into a useable component for manufacturers. The task of getting high dimensional accuracy while producing smaller parts is extremely difficult.

Hence, the engineers measure the parts of the products on three different levels for a precise result. While precision engineers focus on getting the correct size and shape of the components, the precision manufacturers have to ensure the created parts match the specified design.

There is constant pressure on manufacturers to produce the components quickly to meet deadlines without making compromises on their profitability.

Compared to manually created parts, those who use precision engineering machines for manufacturing products get the surety that there won’t any wear and tear in near future.

Since the products made through precision engineering have a longer life, the overall cost is less compared to manually manufactured products that only last for a few months.

The manufacturers mainly use precision engineering because it produces the result quickly and without the need for regular inspection. They need to make products in bulk quantity and depending on manual manufacturing process can significantly reduce the speed of their work.

Precision engineering is extremely reliable for mass production. It also reduces the chances of any error that can be caused in the manual manufacturing process. Let’s understand precision engineering in detail.

What Is Precision Engineering?

The manufacturing process in which the parts with high specifications are precisely engineered is known as precision engineering.

Using precision machines and computers, you can create different parts with the knowledge of programming. There are numerous advantages of precision engineering and it is continuously getting utilized by developers around the world.

CNC Machines In Precision Engineering

CNC machines are popularly used to produce parts with precise dimensions as the manufacturers specified. These machines can be used to remove extra materials from different components in order to create something useful.

CNC machine was first created with help of computer programmers in the 1970s. It gained tremendous popularity within a decade as it brought a revolution in the way products were manufactured. Due to this machine, manufacturers started shifting from creating hand-made parts to precise devices with fewer errors.

The manufacturers are able to produce a large number of products and meet deadlines and high demand from people around the world. From robotic medical devices to aircraft, everything is critically designed and produced through the help of CNC machines and precise engineering.

Various doctors and dentists need the help of these experts to get implants and replacement parts.

Manufacturers with great ideas can start hiring CNC machine programmers and experts to produce products in bulk quantity and increase the number of sales. The demand for this machine is rising with the popularity of science and technology.

Three Measurements In Precision Manufacturing

1. Verification of Accuracy

While determining the accuracy, the person checks how close the output is to the desired signal value.

2. Checking Precision

In this stage, the engineer checks to which degree the output varies from one point to another. Since the manufacturing process, as well as products, is expensive, the engineers work towards getting precise results over accuracy.

3. Meeting Tolerance Range

This is a pre-determined stage in which the person can accept the variation in precision. When it comes to engineering parts, the manufacturers believe that the product can be precise without being completely accurate. They have set an acceptable error range and made it easier for engineers to achieve accuracy and precision at the same time.

Conclusion

We hope now you understand precision engineering and how they measure products for precision and accuracy. You should contact precision engineering experts to get any help related to manufacturing parts of the product.

0 Comments